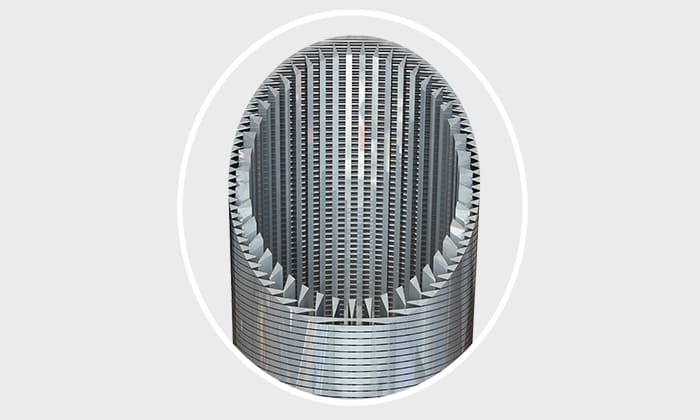

CFL con-slot® Profile Wedge Wire Screens

World class process design and manufacture of high integrity profile wedge wire screens, filters, process internals and equipment for industrial filtration and separation. We provide engineered solutions, delivered with an intrinsic understanding of industrial processes, uniting safety, performance, and decades of technical expertise. Our dynamic approach to industrial filtration and separation solutions is demonstrated with ingenuity and engineering excellence, allowing us to provide engineered solutions facilitating the production, transportation and refining of oil and gas, purification of water, the treatment of industrial liquids and gaseous media, and general processes including dewatering, desalination, and separation.

Sophisticated Design - Engineered Solutions

Engineered with precision, CFL con-slot® high performance profile wedge wire screens are specially designed to provide safe and cost effective solutions for solid/liquid and solid/gas filtration and separation, with optimal performance.

Combining high flow rates with outstanding resistance to high loading and differential pressure, CFL con-slot® profile wedge wire screens enable the implementation of sophisticated engineered solutions. We deliver equipment and components with the highest precision and integrity, driven by our commitment to accuracy and technical excellence in everything that we do.

We combine proprietary precision engineered surface and supporting profile wires, with exacting standards and decades of engineering expertise in manufacturing, welding, and machining, to support complexed engineering projects, with world class profile wedge wire screens. Carefully selected parameters combined with high integrity materials such as super duplex, titanium, 6Mo, C276 and alloys 625 and 825, guarantee structural integrity, durability, inherent mechanical strength and erosion and corrosion resistance.

For applications with highly corrosive and erosive environments, and/or elevated temperatures, we offer a number of surface treatments and material enhancements to extend service life

Our purpose is to set the standard in providing innovative filtration and separation solutions, driven by the ever increasing demands for quality, performance, maximum efficiency, environmental sustainability, and safety.

World Class Profile Wedge Wire Screens

With decades of expertise in crafting specialist high integrity internals for critical applications, we deliver highly complexed solutions for the most demanding of environments.

Downstream Oil Refining and Gas Processing

With more than 60 years of combined experience in designing and manufacturing high-integrity process internals for axial and radial flow reactors, gas processing, compression, and transfer, we offer equipment designed for long-lasting performance.

Typical products and equipment include center pipes, outer baskets, scallops, switchgear, catalyst support grids, quench rings, separation trays, quench chests, dead trays, inlet distributors, outlet collectors and baskets, MOL sieves, conical baskets for gas compression, laterals, and nozzles.

Water Treatment

CFL con-slot® profile wedge wire screens and filters are utilised to separate and treat large volumes of water abstracted from lakes, rivers, sea, and ground, for power plants, desalination units, and numerous industrial water treatment applications.

With extensive experience in the process design and manufacture of screens, filters, and specialist internals for solid / liquid filtration and separation, CFL con-slot® profile wedge wire screens stand as a reliable solution for water treatment and purification, designed to safeguard critical assets and enhance plant efficiencies.

Typical applications include ion exchange, catalyst support and recovery, RO protection, dual and multi media filters, nut shell filters, and self cleaning filters.

Chemical and Pharmaceutical Processing and Mining

CFL con-slot® profile wedge wire screens are designed to deliver exceptional filtration and separation solutions, vital for critical industrial processes and equipment.

Our advanced technology ensures superior performance across a wide range of applications, encompassing, washing, drying, fluidising, dewatering, blending, classification, catalyst support and recovery, filter media support and retention, and precious metal recovery.

We provide extensive expertise and experience, fostering collaboration to deliver sophisticated solutions, including debottlenecking and optimisation of equipment and processes, providing enhanced product quality and throughput, driving improved plant efficiencies and prolonged production cycles.

Upstream Oil and Gas Production

For more than four decades, CFL con-slot® profile wedge wire screens have been instrumental in providing engineered solutions for sea water treatment, produced water treatment, and sand control, for global oil and gas operations, serving both topside and subsea applications.

Seawater is used extensively for cooling, firefighting, potable water production, injection, and secondary EOR.

Produced water treatment is a critical aspect of oil and gas operations. Produced water often contains contaminants such as oil, grease, salts and heavy metals. Effective treatment employing equipment such as solids removal screens, nut shell filters, and dual media filters are essential, not only for environmental protection but also for regulatory compliance, operational efficiency and secondary and tertiary treatment, prior to re-injection.

We provide process and mechanical design and manufacture of specialist internals and equipment, including retrofits and upgrades of poorly performing equipment, offering solutions for debottlenecking and optimisation, enhancing efficiency and reducing environmental risks.

FORMATIONLINK™️ Well Screens

CFL con-slot® FORMATIONLINK™️ is an innovative slotted screen for oil, gas, and water exploration and production. It offers a single filtration surface that promotes laminar flow and radial filtration of reservoir fluid.

The unique design of FORMATIONLINK™️ dramatically reduces stagnant zones, screen surface fouling, and erosion damage, thus reducing hydraulic losses during injection of fluids into the well.

General Process

CFL con-slot® profile wedge wire screens represent a versatile and efficient solution for many industrial processes and applications, including paint production, aquaculture, paper and pulp processing, sugar production, food and beverage, gasification, cosmetics and toiletries and sludge thickening.

Overall, CFL con-slot® profile wedge wire screens offer robust performance, high durability, and precise filtration and separation capabilities, making them indispensable components in a wide range of industrial processes and applications. Their versatility and effectiveness make them a preferred choice for industries seeking reliable long term solutions for solid/liquid and solid/gas separation and filtration requirements.

We Design, Engineer and Deliver

CFL brings extensive experience in designing and manufacturing screens, filters, and specialist internals for solid / liquid and solid / gas filtration and separation.

Key Benefits & Features

- Inherent mechanical strength and durability

- Resistance to clogging and fouling

- High load capability

- Precise slot openings

- Reduced maintenance

- Low operating costs

- High flux rates

- Uniform distribution of flow

- Versatile custom design

- Efficient separation

- Improved product quality

- Enhanced erosion and corrosion properties

Industrial Applications

- Paper and pulp processing

- Oil refining

- Municipal and industrial water treatment

- Brewing and distilling

- Mineral processing

- Drilling fluid management

- Water reclamation

- Environmental remediation

- Hydroelectric power generation

- Hydraulic fracturing

- Irrigation

- Syngas treatment