How do high-quality filtration systems deliver a longer-term investment?

How do high-quality filtration systems deliver a longer-term investment?

When it comes to improving operational efficiency and reducing costs, investment in high-quality filtration isn’t always top of the list. For some businesses, their filtration system is simply seen as a basic necessity — just something to get the job done. However, the reality is that the quality of your filtration system has a significant impact on your overall performance, safety, and bottom line.

Low-cost filters might seem economical in the short term, but they often come with hidden costs — frequent replacements, downtime, energy inefficiencies, poor results, and even equipment damage. In contrast, investing in a high-quality filtration system pays off by improving reliability, protecting assets, and saving money over time.

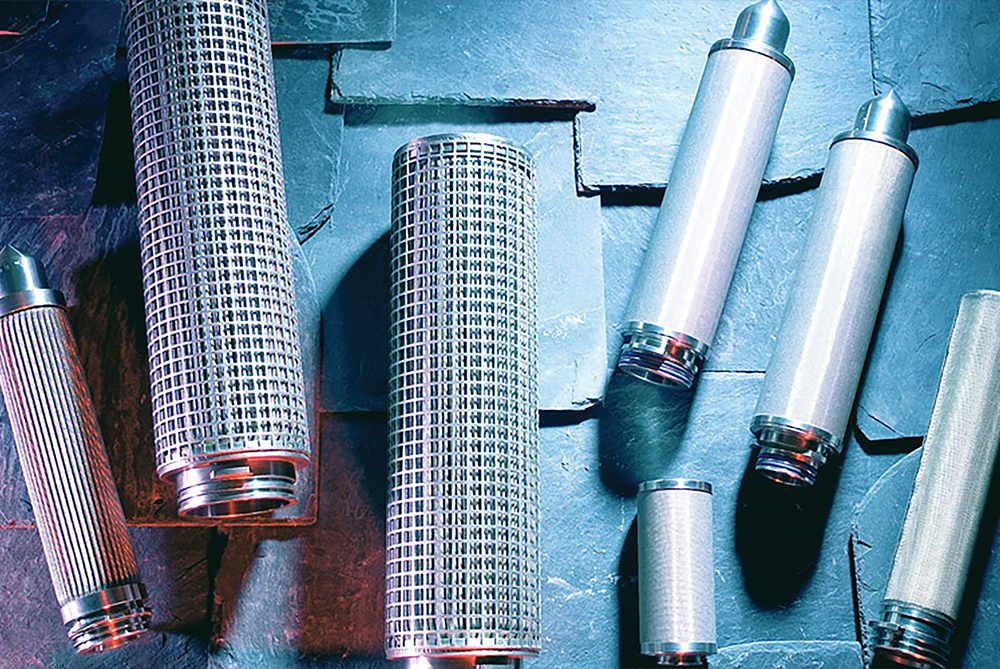

At CFL, we specialise in precision-engineered filtration systems built for performance, durability, and efficiency. With years of engineering expertise across a range of industries, we understand how to create solutions that not only filter and separate but also add value. Let’s explore how investing in high-quality filtration helps you save money in the long run.

1. Fewer replacements, lower maintenance costs

One of the primary financial benefits of high-quality filtration is reduced maintenance costs. Lower-grade filters tend to foul more quickly, degrade more rapidly, and require more frequent changeouts. Not only does this drive up your consumable costs, but it also increases downtime and labour hours spent maintaining the system.

CFL’s filtration solutions are engineered to last longer. With high filtration capacity and durable construction, they maintain optimal performance over extended service intervals. This reduces the need for constant replacements, reduces labour input, and keeps your system running efficiently with minimal interruption.

2. Enhanced process efficiency

When your filtration system isn’t working correctly, your entire process suffers. A fouled or inefficient filter can result in premature pressure loss, reduced flow rates, and inconsistencies in production. These issues result in higher energy consumption, slower operations, and even product waste.

CFL’s filters are designed for precision and consistency. They ensure smooth, uninterrupted flow, effective contaminant removal, and optimal performance across varying process conditions. That means fewer disruptions, better control over your production line, and reduced operational costs over time.

3. Protecting your equipment investment

Your equipment is among the most valuable assets in your facility. Pumps, valves, heat exchangers, and sensitive instrumentation can be severely damaged by contaminants that aren’t efficiently removed. Even small particles can cause wear, leading to premature breakdowns or complete equipment failure.

With CFL’s filtration solutions, you get a high level of protection. The filters are specifically designed to retain fine particulates and protect downstream equipment from damage. This not only extends the lifespan of your equipment but also reduces the cost of repairs and capital replacement.

4. Minimised downtime

Unplanned downtime can be extremely costly, particularly in high-output environments. A failed filter or a fouled line can halt production unexpectedly, leading to missed deadlines, financial losses, and client dissatisfaction.

High-quality filtration and separation are one of the most effective ways to minimise the risk of downtime. CFL’s filters are designed for reliability and performance stability, even in the most demanding applications. With fewer failures and longer run times, your operation stays online and productive — safeguarding both revenue and reputation.

5. Improved product quality and compliance

Filtration and separation play a crucial role in ensuring product quality, especially in industries such as food and beverage, pharmaceuticals, and chemicals, where strict hygiene and purity standards must be met. A substandard filter can lead to contamination, product recalls, or regulatory penalties.

CFL’s filtration solutions are engineered to deliver accurate, repeatable filtration every time. This ensures that your output meets required specifications and industry standards, helping you avoid waste, rework, and reputational risk. Better product consistency leads to better client satisfaction — and fewer costly mistakes.

6. Greater energy efficiency

Filtration and separation directly affect the amount of energy your process consumes. If a filter becomes fouled quickly or causes excessive pressure drop, your pumps and systems must work harder to maintain performance. That extra strain is reflected in your energy costs.

CFL’s filters are designed to maintain low differential pressure and smooth flow, even under high loads. That efficiency means less energy is consumed, reduced wear on supporting equipment, and lower overall running costs. For organisations focused on sustainability as well as savings, this is a crucial advantage.

7. Less waste through customised solutions

Off-the-shelf filters often don’t meet the specific requirements of specialised systems. Using incompatible material, size, or micron rating can lead to poor performance, material wastage, or process inefficiencies.

At CFL, we work closely with you to design filtration and filtration systems customised to your exact application. Our bespoke approach ensures your filters perform at their best, reduce waste, and integrate seamlessly with your existing equipment. This customisation maximises value and performance, eliminating the cost of trial-and-error filtering.

8. Lower environmental and safety risks

Filtration and separation isn’t only about production — it’s also about protection. Poor-quality filters can lead to safety hazards, environmental breaches, or uncontrolled emissions. These issues come with steep fines, legal liabilities, and reputational damage.

Our high-quality filters significantly reduce these risks. They prevent hazardous contaminants from escaping into the environment and help you stay within regulatory limits. Optimal filtration and separation also means safer conditions for your workforce, reducing the risk of injury or exposure to harmful substances.

9. Long-term return on investment

The key to smart spending in any industry is to consider the long-term perspective. When considering filtration and separation, the total cost of ownership includes much more than the purchase price. Maintenance, energy use, product waste, downtime, and equipment damage all contribute to the overall cost.

CFL’s filtration solutions are built to deliver value well beyond their initial cost. With reduced maintenance, increased uptime, enhanced protection, and improved efficiency, CFL’s filters provide a return on investment that far exceeds that of cheaper alternatives.

10. Backed by engineering expertise

The performance of your filtration and separation system depends on more than just the product — it depends on the people behind it. At CFL, our engineering team brings decades of real-world experience to every solution we develop. We don’t just sell filters; we provide expert guidance, technical support, and ongoing partnership.

From consultation to system design, installation to maintenance, we’re with you at every step. Our clients trust us because we deliver systems that work, perform, and last.

Final thoughts

Filtration and separation isn’t a corner to cut. While low-cost options may appear to save money, they often prove more expensive in the long term — in of downtime, repairs, energy bills, and lost productivity.

At CFL, we recognise the benefits of well-engineered filtration and separation for your businesses. Our systems are designed for optimal performance, durability, and reliability. We help clients reduce costs, protect their investments, and operate more efficiently.

If you’re looking to make smarter, long-term decisions for your operation, start with your filtration and separation.

Latest News

How CFL’s filtration and separation solutions outlast conventional systems

Profile Wedge Wire or Woven Wire Mesh? Choosing the Optimal Solution for Process Efficiency and Optimisation

When is filtration and separation equipment rental the best option?

How do high-quality filtration systems deliver a longer-term investment?

Investing in future champions: CFL’s commitment to supporting local youth sports

No comments yet.