Custom filtration solutions: How CFL engineers products for unique industry challenges?

Custom filtration solutions: How CFL engineers products for unique industry challenges?

In today’s demanding industrial landscape, achieving optimal purity, operational safety, and peak efficiency frequently depends on highly specialised filtration systems. Standard, off-the-shelf solutions often prove inadequate when faced with the unique conditions of the wide variety of filtration requirements. CFL demonstrates its profound expertise, offering custom filtration solutions meticulously engineered to address the distinct challenges encountered across a multitude of industries.

This blog explores CFL’s dedicated approach, showcasing how its significant engineering capabilities are synergised to deliver targeted, effective solutions, ensuring operational excellence from automotive manufacturing to critical processes in the nuclear and pharmaceutical sectors.

Why do standard filtration solutions fall short?

Modern industries operate under a spectrum of demanding conditions that render standard filtration inadequate. The need for custom solutions is driven by:

- Diverse process materials: From volatile chemicals and viscous slurries to delicate biologics and ultra-pure gases, each substance presents unique filtration characteristics.

- Extreme operating conditions: Many processes involve elevated temperatures, high pressure, abrasive particulates, or sterile environments that demand specialised materials and robust designs.

- Stringent regulatory landscapes: Sectors such as pharmaceuticals, food and beverage, and nuclear power operate under exacting regulations that necessitate validated and compliant filtration.

- Consequences of failure: Inadequate filtration can result in compromised product quality, equipment damage, safety hazards, and environmental violations, leading to significant costs.

Customised filtration solutions across key industries

CFL’s expertise is prominently demonstrated by its proven ability to address the specific and often severe filtration challenges inherent to a wide spectrum of industries.

Automotive Sector

The automotive industry’s demand for high-quality finishes and precision-engineered components makes effective filtration indispensable.

Key Filtration Demands:

- Maintaining cleanliness in paint and coating loops (e.g., E-coat, phosphate systems).

- Ensuring the purity of parts washing fluids.

- Effective coolant filtration for tool longevity and improved surface finish.

CFL's Engineered Solutions:

- We engineer specialised bag and cartridge filters to remove particulates from paint lines, preventing defects and ensuring flawless finishes.

- Robust filtration systems are provided for machine coolants and washing stations, enhancing production quality, reducing waste, and improving operational efficiency.

Chemical & Pharmaceutical Industries

These sectors demand exceptional purity, containment, and safety in all processes.

Key Filtration Demands:

- Filtration of fine chemicals, Active Pharmaceutical Ingredients (APIs), and solvents.

- Efficient catalyst recovery.

- Sterility of process utilities (steam, air, water).

- Handling of aggressive or hazardous materials, often requiring ATEX compliance or adherence to GMP guidelines.

CFL's Engineered Solutions:

- Systems are designed with appropriate material compatibility (e.g., stainless steel, Hastelloy®) for corrosive chemicals.

- For pharmaceutical applications, CFL offers sanitary-design cartridge and bag filter housings, alongside other specialist filter internals and associated process equipment, ensuring product purity and regulatory compliance.

Food & Beverage Sector

Product quality, safety, and consistency are paramount in food and beverage processing.

Key Filtration Demands:

- Clarification of products such as beer, wine, and edible oils.

- Ensuring microbial stability and ingredient integrity.

- Filtration of syrups and provision of high-quality process water.

- Adherence to stringent FDA and EU food contact regulations.

CFL's Engineered Solutions:

- Hygienic filtration solutions, including stainless steel filter elements and specialist internals, for applications such as edible oil polishing, and cartridge/bag filters for beverage clarification, are provided.

- Materials of construction are meticulously selected to be food-grade, preventing any impact on taste, odour, or appearance.

Mining Industry

The mining sector requires durable, robust filtration and separation equipment capable of handling abrasive materials and large volumes.

Key Filtration and Separation Demands:

- Efficient dewatering of mineral slurries and tailings.

- Treatment of large volumes of process water for reuse or discharge.

- Robust solutions for product washing and grading.

CFL's Engineered Solutions:

- Precision, high-quality centrifuge screens and baskets.

- Robust heavy-duty screens, baskets and metallic filters dewatering, designed for high solids handling and abrasion resistance.

- Basket strainers and self-cleaning filters ensure reliability for process water treatment in demanding environments.

Nuclear, Aerospace & Defence

Key Filtration Demands:

- Filtration of radioactive waste streams and nuclear reactor coolants.

- Purification of hydraulic fluids in aerospace applications.

- Specialised filtration for various defence systems.

CFL's Engineered Solutions:

- CFL engineers high-integrity filtration systems, often incorporating specialised alloys and designed to meet exacting standards such as ASME codes.

- Our solutions prioritise safety, containment, and long-term reliability for critical applications where failure is not an option.

Oil, Gas & Energy Sector

Key Filtration Demands:

- Separation of produced water to meet environmental discharge limits.

- Seawater coarse and fine filtration for cooling, fire fighting and fresh water supply.

- Seawater injection for enhanced oil recovery.

- MEG/TEG recovery and amine sweetening in gas processing.

- Fuel gas conditioning and lube oil filtration, often requiring compliance with NORSOK/API standards.

- Filtration for renewable energy sources such as geothermal and biomass.

CFL's Engineered Solutions:

- Robust solutions for a number of applications, including seawater coarse strainers and fine filters, deoiling hydrocyclones, nut shell filters, multi-media and dual filters, cartridge filters, bag filters, and specialised process internals, engineered using specialist materials.

- Customised skid systems are designed for reliability in harsh operating conditions across oil, gas, and renewable energy applications.

Water Treatment

Key Filtration Demands:

- Removal of suspended solids, sediments, chemicals, and microorganisms from incoming process water.

- Treatment of industrial wastewater to meet environmental compliance.

- Filtration for cooling water systems and the production of potable water.

CFL's Engineered Solutions:

- A broad array of technologies is offered, including multimedia filters, cartridge, bag, self-cleaning filters and carbon filters.

- Solutions are customised to the specific contaminants and flow rates of each water treatment application, ensuring efficiency and regulatory adherence.

Partnering with CFL: Key Advantages

- Collaborative Engineering: Close collaboration with clients to understand precise needs and co-create optimal solutions.

- Bespoke Design: Development of systems truly customised to each unique application, moving beyond standard offerings.

- Problem-solving Focus: We apply our extensive experience and know-how to solve the most complex filtration and separation challenges – providing dependable, effective solutions.

- Quality and Reliability: The manufacture of equipment to the highest standards for dependable, long-term performance.

- Enhanced Efficiency: Design of solutions that can improve process efficiency, reduce waste, and lower operational costs.

- Compliance Assurance: Engineering of systems that help clients meet stringent industry and environmental regulations.

Conclusion

CFL is recognised globally as a benchmark for engineering excellence in customised filtration and separation solutions.

Our proven ability to deliver high-integrity solutions and systems, underpinned by world-class project management and a deep understanding of complex industrial challenges, positions us a trusted, indispensable partner.

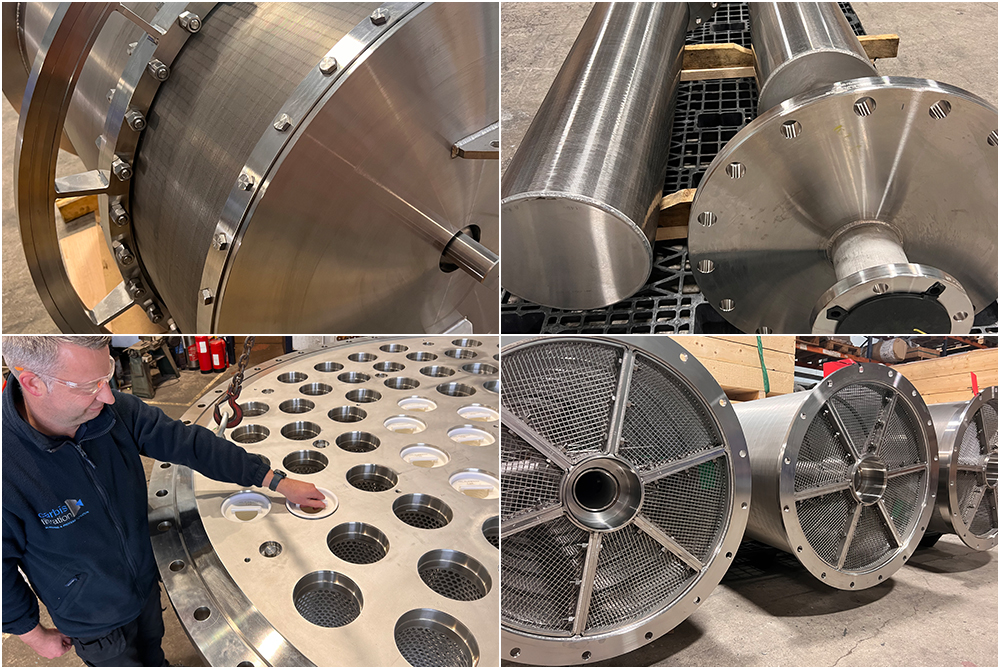

By seamlessly integrating specialist fabrication, precision machining, and expert welding with a commitment to continuous innovation, CFL consistently delivers engineered filtration and separation solutions that set the standard for, reliability, performance and long-term value.

Latest News

How CFL’s filtration and separation solutions outlast conventional systems

Profile Wedge Wire or Woven Wire Mesh? Choosing the Optimal Solution for Process Efficiency and Optimisation

When is filtration and separation equipment rental the best option?

How do high-quality filtration systems deliver a longer-term investment?

Investing in future champions: CFL’s commitment to supporting local youth sports

No comments yet.